Complete solutions for complex tasks

Whether you are flame heating or straightening, preheating (welding and cutting), post-heating (welding), hot forming, flame brazing, flame hardening or fusing flame-sprayed coatings, you want to be sure you are using the appropriate gas and the best equipment. Linde can help you make the right decision. Our complete LINDOFLAMM® flame solutions ensure that you always deliver the optimum performance with the highest possible cost-efficiency.

The classic combination: oxygen and acetylene

Special manufacturing processes call for special solutions. The use of standard, off-the-shelf

burners is often an unsatisfactory compromise. The LINDOFLAMM® flame solutions are designed to fulfil your unique

requirements, utilising special burners whose shapes and capacities are tailored to your application and are

matched with the right fuel gas mixture.

Benefits at a glance

- ● Lowest processing costs: economical gas use

- ● Highest productivity: optimum heat transfer to

the workpiece since the technology and the gas are fitted to the task - ● Possibility of mechanisation

The classic combination: oxygen and acetylene

Acetylene is the perfect fuel gas, when efficiency,

precision and accuracy are

required. It produces the highest temperatures, has the lowest moisture content in exhausted gases and has the

highest flame propagation rate.

Oxygen is used for hot forming, flame hardening, flame cleaning and

fusing of sprayed

coatings. It gives a rapid rise in temperature and causes a build-up of heat with a high temperature gradient

inside the workpiece.

Compressed air lowers the temperature and combustion velocity,

producing a mild and gentle, yet

intense and

economical flame.

Global knowledge and process know-how

Tailor-made solutions require extensive process know-how and experience to achieve the desired results in the most efficient way. Our local technical experts meet this demand down to the last detail.

Your enquiry

Fill in the form below and we will contact you to discuss more.

Initial consultation

Upon receipt of your enquiry, a technical support engineer will arrange to visit you to discuss your exact requirements.

Demonstration/trials

We will arrange a demonstration for you and, if appropriate, conduct trials on your workpieces at your production facility.

Solution design

A solution will be tailored to your needs. If necessary, we will talk to your machine builders or engineers to design the integration of our equipment.

Proposal

The solution will be presented to you for your consideration.

Installation

Once you are satisfied with our solution design, a project plan will be agreed upon and our customer engineering service will arrange for the installation of the system (cooperating with your machine builders or engineers where necessary).

Commissioning

Our technical support engineers will start up the system and optimise it according to your needs. They will train your operators and will hand over the system.

Support

We will provide continued support to ensure that you are happy with your system and that it meets your requirements. We will promptly respond to any problem that may occur.

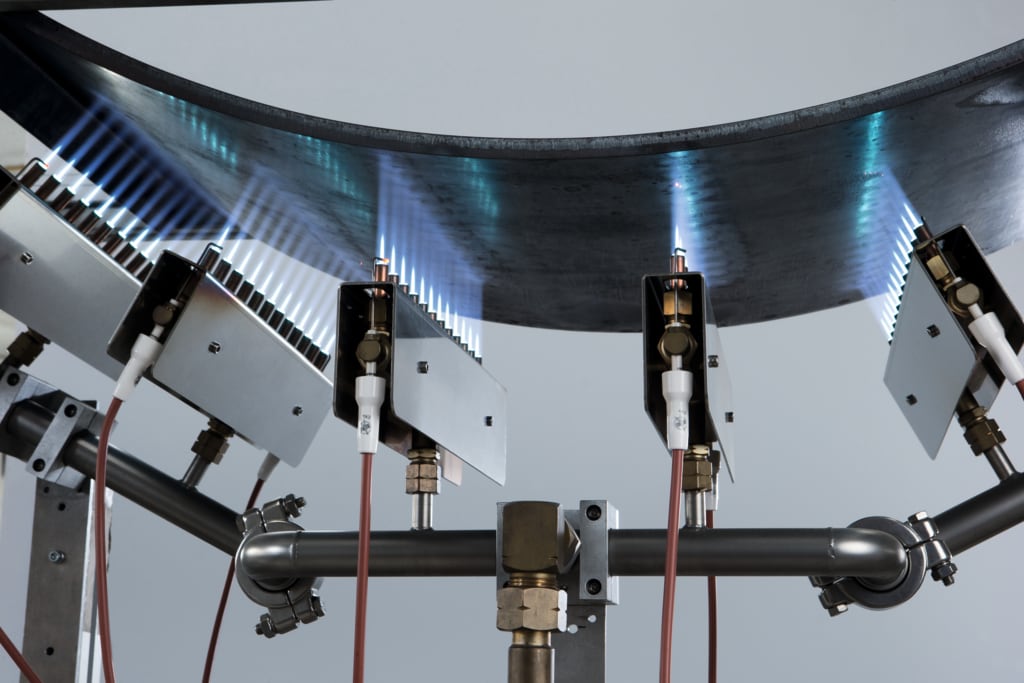

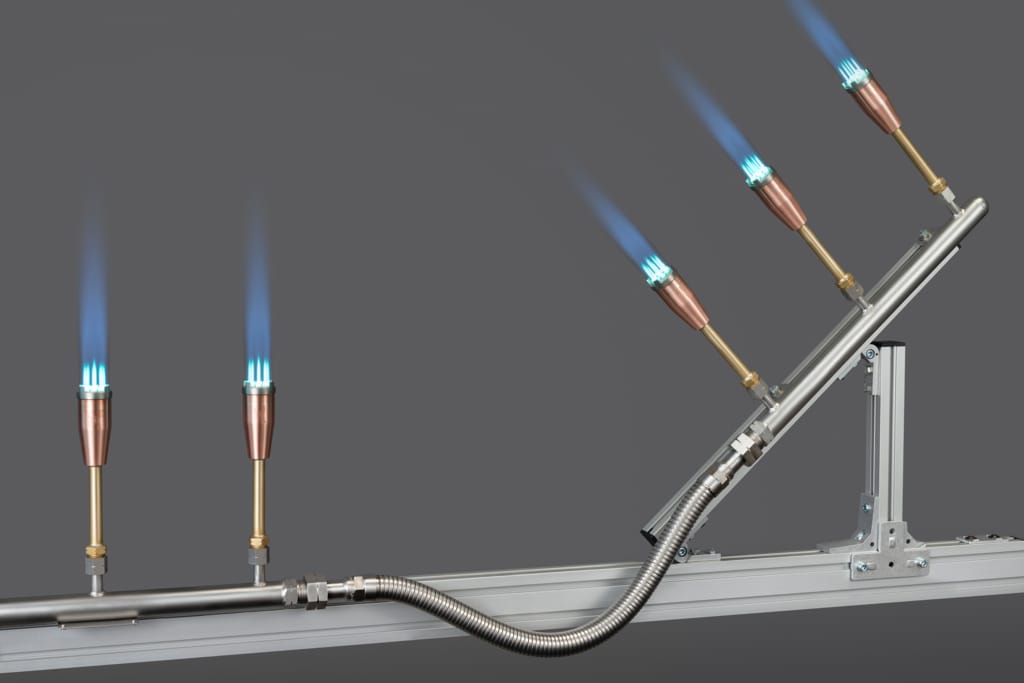

LINDOFLAMM® special burners

Our all-round heating solutions for semi- and fully automated

heating processes are tailored to customer requirements and deliver outstanding results. At the heart of each

heating installation is the LINDOFLAMM burner.

Further components and services – from automatic ignition to

monitoring, temperature control and documentation – put the perfect finish on our offering.

Linde's unique LINDOFLAMM burner design allows easy movement to tackle multiple deformations in large surfaces.

What do customers say?

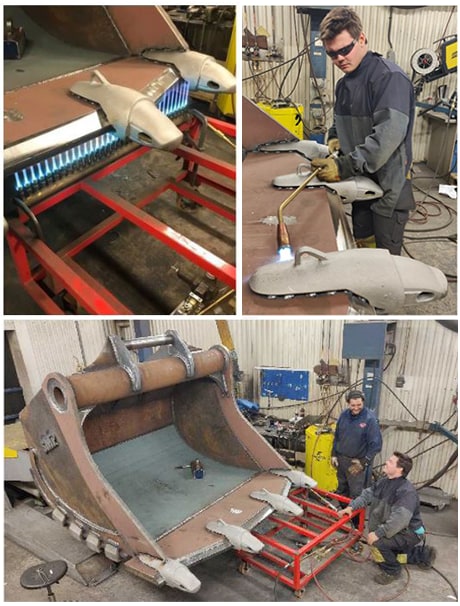

Pon CAT Norway use LINDOFLAMM® burner technology in their work with pre-heating and welding of “Knives” and adapters for excavator buckets, in joining with HARDOX® and STRENX®.

“It’s no doubt that LINDOFLAMM® is highly effective and fast to use in this process. We are very satisfied with the solution and the time we use is reduced rapidly. It is also highly effective compared to older methods.”

Arild Berg

Head of Welding department, Pon CAT

What do customers say?

SMP Parts saves time and money using LINDOFLAMM® flame solutions

“When I first heard about LINDOFLAMM, I have to admit it sounded too good to be true. But it works – and it’s saving us time and money. Since introducing LINDOFLAMM, a process that used to take 45 minutes now takes about 7 minutes and nobody has to stand holding the burner.”

Thomas Sandin, Head of Welding

Read more →

Downloads

Downloads

| Safety datasheets | Product datasheets & brochures |

|---|---|