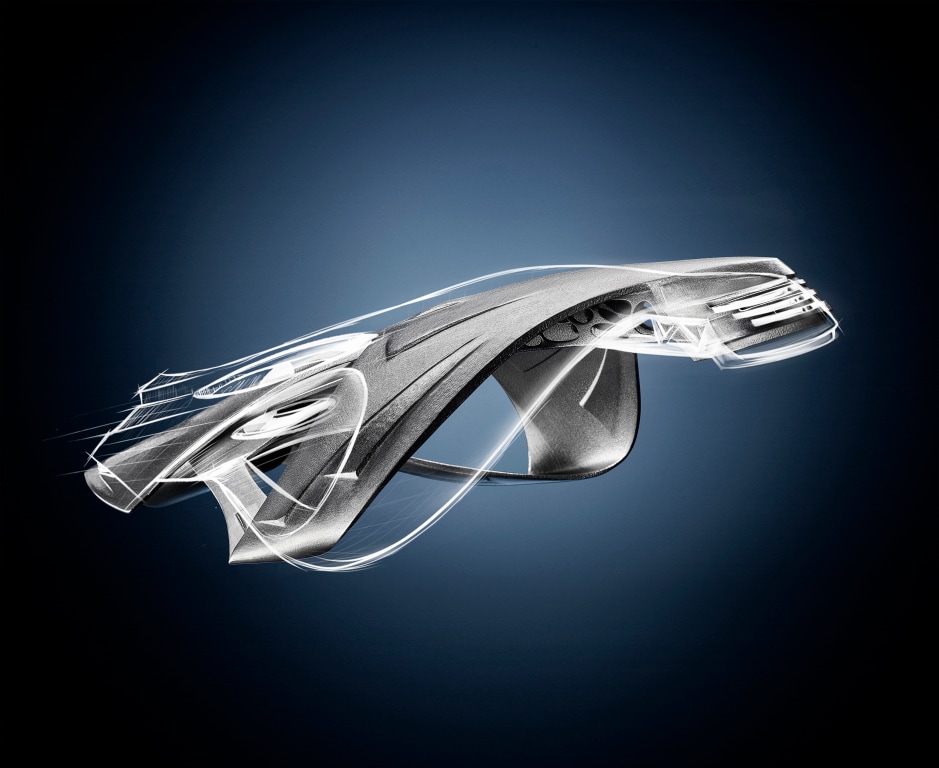

Revolution in Manufacturing

Additive Manufacturing has revolutionized the way things are made. It has opened up new and exciting opportunities for designers, customers and industry. Even complex geometries can be manufactured at low cost and in a short time. It enables extensive customization and production flexibility. Additive Manufacturing has evolved from prototyping to mass production.

As in all manufacturing processes, the quality of the end product heavily relies on the properties of the base material and the precision of the machines. Process gases therefore play a crucial role in Additive Manufacturing and are involved in every stage of the AM production chain, from the manufacture of metal powder to surface treatment. Thanks to Linde's gas and metal expertise, we have been a significant partner since the early stages of Additive Manufacturing, helping to find the right supplier of world-class industrial and specialty gases and gas delivery solutions.