Different processes to achieve the best welding result

We provide end-to-end solutions to meet all of your individual welding related process needs from brazing in high temperatures to flame spraying to improve the surface’s resistance to corrosion.

Welding related areas

- Brazing and soldering

- Flame heating

- Gouging

- Thermal spraying

- Flame straightening

- Flame cleaning

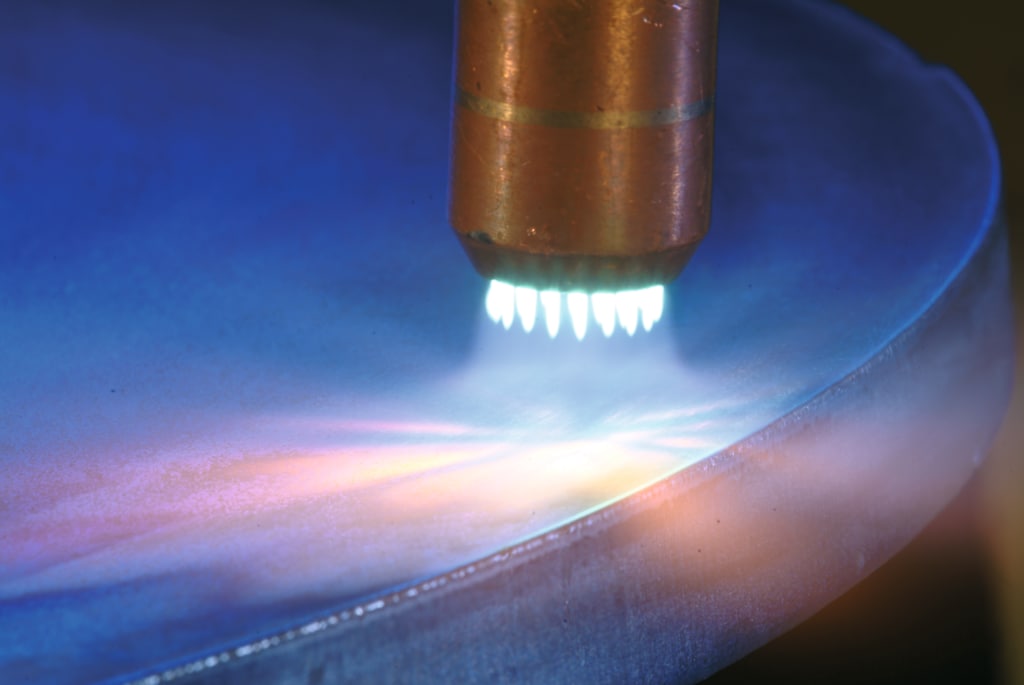

Brazing and soldering

In both brazing and soldering, the solder is added in between the surfaces to be joined through capillary

action. In soldering the working temperature is below 450 °C and it is suited for welding copper and copper

alloys, zinc, steel aluminium and aluminium alloys. In brazing, the working temperature is between 450 °C–1000

°C and well-suited for most metals.

Brazing is used, for example, for welding copper pipes in the production of bathroom fixtures and for fastening

pieces of hard metal to saw blades and drill bits. Soldering provides joints of high quality and high surface

finish. Soldering does not involve the same high working temperature as welding, which gives rise to less

problems with deformations.

Buy products here

Downloads

Downloads

| Safety datasheets | Product datasheets & brochures |

|---|---|